Difference between revisions of "Adaptively Controlled Polarization And Hysteresis Curve Tracing For Polymer Piezoelectrics (1 S/B)"

From iis-projects

| Line 5: | Line 5: | ||

==Short Description== | ==Short Description== | ||

| − | In the fabrication process of piezoelectric materials, a polarization step is required to create and maintain a permanent electric dipole moment in the crystal structure of the material. The polarization procedure usually involves applying a high electric field to the piezoelectric material over a period of time. This field creates an electric polarization in the material by reorienting the crystal structure and aligning the electric dipoles in the direction of the electric field. | + | In the fabrication process of piezoelectric materials, a polarization step is required to create and maintain a permanent electric dipole moment in the crystal structure of the material. The polarization procedure usually involves applying a constant or alternating high electric field to the piezoelectric material over a period of time. This field creates an electric polarization in the material by reorienting the crystal structure and aligning the electric dipoles in the direction of the electric field. |

To measure the success rate of the polarization process, the polarization of the material is plotted against the applied electric field. The frequency response of the applied signal results in a hysteresis-shaped curve which is used to asses the materials piezoelectric properties. | To measure the success rate of the polarization process, the polarization of the material is plotted against the applied electric field. The frequency response of the applied signal results in a hysteresis-shaped curve which is used to asses the materials piezoelectric properties. | ||

| − | Due to the high electric fields and often unknown material parameters, manual control of such equipment can be difficult. The aim of this thesis is to devleop a microcontroller based | + | Due to the high electric fields and often unknown material parameters, manual control of such equipment can be difficult. The aim of this thesis is to devleop a microcontroller based strategy for the polarization and testing of piezoelectric polymeres |

Revision as of 08:31, 8 February 2023

Contents

Short Description

In the fabrication process of piezoelectric materials, a polarization step is required to create and maintain a permanent electric dipole moment in the crystal structure of the material. The polarization procedure usually involves applying a constant or alternating high electric field to the piezoelectric material over a period of time. This field creates an electric polarization in the material by reorienting the crystal structure and aligning the electric dipoles in the direction of the electric field.

To measure the success rate of the polarization process, the polarization of the material is plotted against the applied electric field. The frequency response of the applied signal results in a hysteresis-shaped curve which is used to asses the materials piezoelectric properties.

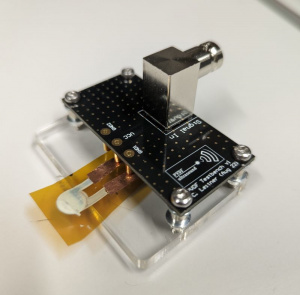

Due to the high electric fields and often unknown material parameters, manual control of such equipment can be difficult. The aim of this thesis is to devleop a microcontroller based strategy for the polarization and testing of piezoelectric polymeres

Status: Available

- Looking for 1 Semester/Bachelor students

- Contact: Christoph Leitner

Prerequisites

- Analog Mixed Signal Design

- PCB Design

- Microcontrollers

Character

- 20% Literature research

- 40% PCB Design

- 30% Microcontroller programming

- 10% Testing

Professor

Detailed Task Description

Goals

Practical Details