Towards Flexible and Printable Wearables

From iis-projects

Contents

Overview

Flexible and printable electronics have emerged as promising technologies with vast potential for revolutionizing various industries. These technologies enable the creation of electronic devices that can be bent, twisted, and seamlessly integrated onto flexible substrates. This opens up new possibilities for applications in wearables, healthcare, smart clothing, and more.

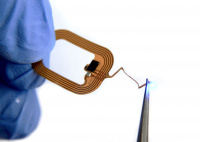

The use of flexible and printable materials, such as organic semiconductors, conductive polymers, and nanomaterials, allows for the fabrication of lightweight, thin, and conformable electronic devices. These materials possess inherent flexibility, enabling the development of sensors that can smoothly integrate onto flexible and dynamic surfaces. Additionally, the additive manufacturing processes associated with these technologies enable cost-effective and rapid prototyping, making them highly accessible for experimentation.

Project description

In this moonshot project, the student will research comprehensive literature to establish a strong foundational understanding of printable electronics. Following the literature research, the student will focus on becoming familiar with the Voltera NOVA printer, a promising tool for additive manufacturing in printable electronics. This printer will serve as a practical platform for the student to explore and experiment with printable materials and their properties.

Additionally, the student will delve into possible sensing applications within the realm of printable electronics. By leveraging the unique properties and capabilities of printable materials, the aim is to identify and explore potential sensing applications. This exploration will involve understanding the characteristics, limitations, and possibilities of these materials in the context of sensing. Finally, the project seeks to address one or multiple of the following challenges within the field of printable electronics. These challenges include:

Energy Supply – Exploring innovative approaches for providing a sustainable and long-term power source for highly integrated flexible devices. This may involve investigating energy harvesting techniques such as RFID/NFC, flexible solar cells, or piezoelectric elements.

Sensing – Identifying and developing sensing applications using printable materials. This may involve exploring force sensors for human-machine interfaces, ECG electrode tattoos, ultrasound transducers, and other potential sensing applications.

Communication – Overcoming the limitations of energy and circuit complexity to enable efficient and reliable communication within fully flexible sensing systems. This could involve exploring backscattering techniques or other communication methods suitable for printable electronics.

Hybrid integration – Addressing the mechanical interface challenges when combining printable devices with conventional circuit manufacturing techniques. Finding ways to seamlessly integrate and ensure the functionality of soft and rigid electronic subsystems.

Tasks:

- Simulation and circuit design

- ECAD / MCAD design

- Manufacturing and testing of prototypes

Prerequisites depending on tasks (not all required)

- Creativity and solid research methodology (highly appreciated)

- Circuit design tools (e.g., Altium Designer)

- Additive manufacturing know-how and knowledge of MCAD tools (e.g., SolidWorks)

Type of work

- 33% Literature study

- 34% System design and implementation

- 33% Measurements and validation

Status: Available

- Type: Bachelor, Semester, or Master Thesis (multiple students possible)

- Professor: : Prof. Dr. Luca Benini

- Supervisors:

Philipp Mayer

|